TPU 95A HF

TPU 95A HF

Flex That Survives the Real World

With an ultra-high elongation—stretching over 650% before snapping—and a tensile strength of about 27 MPa, this TPU stays flexible without breaking, even after repeated stress. It’s designed to handle real-world demands—drop after drop, bend after bend.

Soft Meets Strong

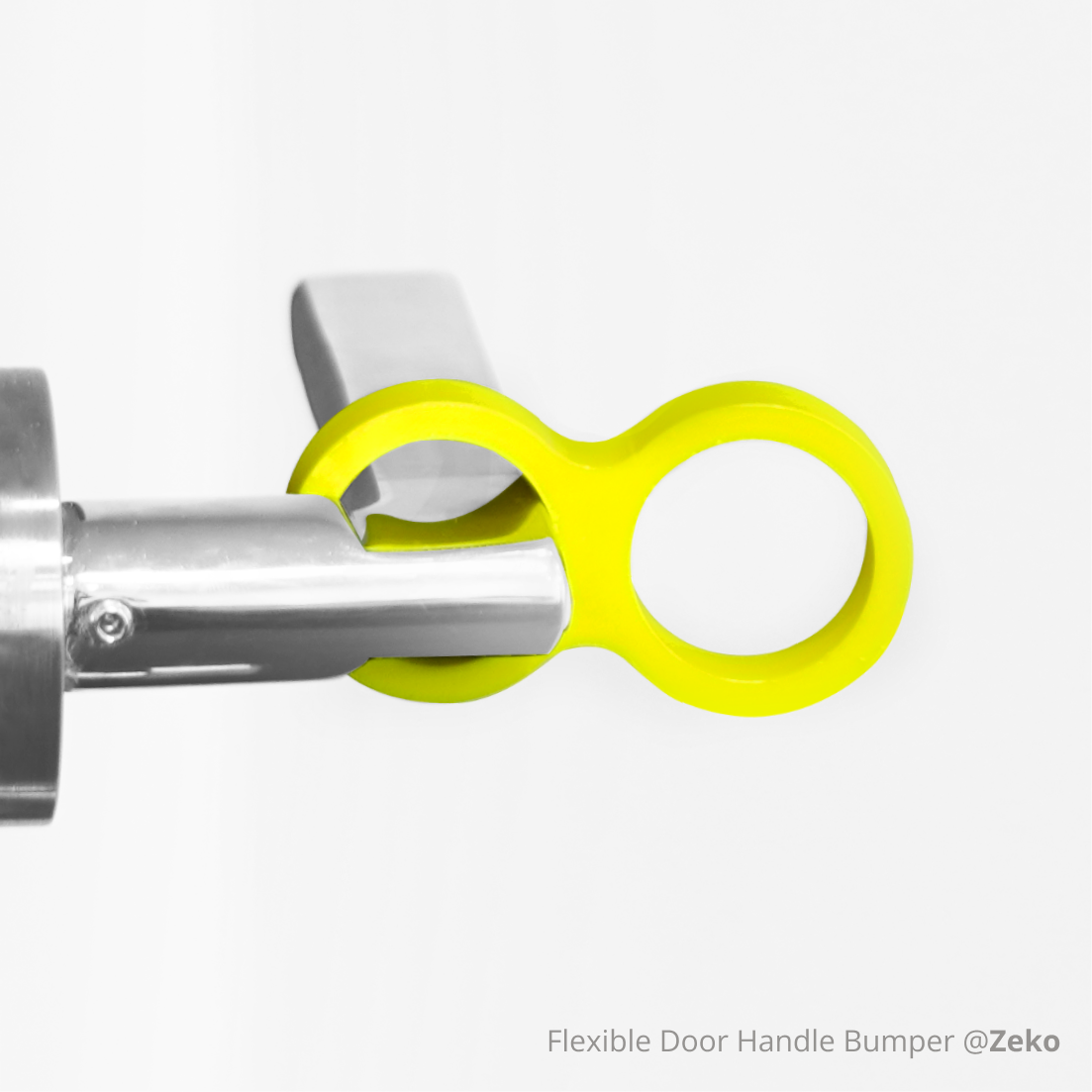

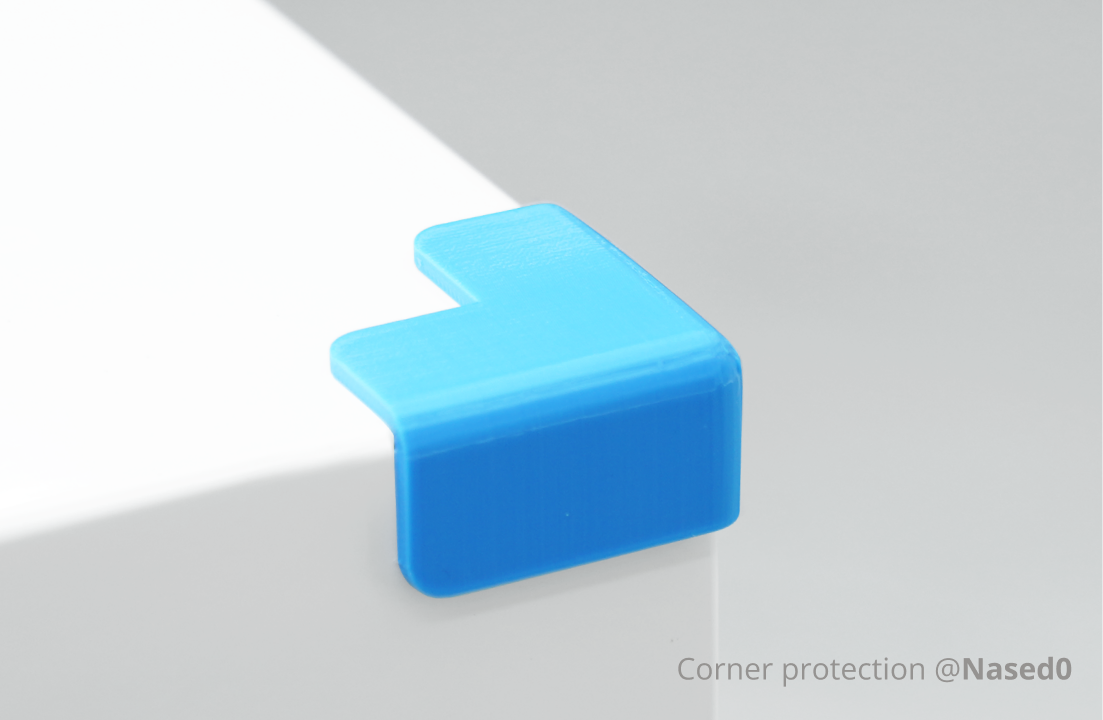

At Shore 95A, it falls in that sweet spot: stiff enough to resist sagging, yet soft enough for functional flexibility. Ideal for grips, bumpers, protective covers, and wearable parts.

Engineered for Durability

Its impact resistance is through-the-roof—roughly 123 kJ/m² in-plane and about 86 kJ/m² across layers. It soaks up shocks and rebound with ease, and, at -20 °C, stays elastic, not brittle.

No Compromise on Beauty

Delivering a clean, rubbery matte finish, finished parts feel good and look professional with zero sanding or post-processing.

Heads-Up: Moisture Awareness

This TPU loves moisture—send it to a dry box when not in use, and dry before printing to keep it performing flawlessly (even though prints don’t require drying).

🔧 Best For:

-

Flexible parts that take hits: bumpers, feet, seals

-

Wear-resistant components: grips, sleeves, protective covers

-

Elastic mechanical elements: springs, flex hinges, shock absorbers

Why It Matters:

| Property | Why You’ll Care |

|---|---|

| Tensile Strength ~27 MPa | Strong under tension—won’t rip under load |

| Elongation >650% | Stretchy durability—bounces back every time |

| Impact Strength 123 kJ/m² (XY) | Absorbs shocks—great for rugged use |

| Shore Hardness 95A | Balanced feel—not floppy, not rock-hard |

| Cold-Temp Resilience | True elasticity in sub-zero environments |

| Moisture-Sensitive | Needs drying—professionally maintained performance |

TL;DR: TPU 95A HF brings serious flexibility, durability, and impact resistance—while delivering a sleek matte finish and tactile, rubber-like feel. Tough enough for the real world, stylish enough to stand out.